Application

Three layer rotary drum dryer, known as one of the best efficient combined three cylinder drum dryer, it uses the latest European energy-saving technology, with embedded type structure. Inner cylinder, middle cylinder and outer cylinder form a self insulation structure. Thermal insulation material and stainless steel plate cover the drum, which effectively reduce heat loss, to improve the thermal efficiency. This three cylinder dryer is mainly used for drying certain humidity granular materials, such as yellow sand used in the industries of dry mortar, river sand, quartz sand, garnet sand, as well as use of all kinds of green sand casting industry, building materials industry of blast furnace slag cement, granular viscous soil, no chemical reaction materials, with high temperature resistance in the chemical industry.

Processed Material

Features of Three Layer Drum Dryer

- Triple-drum rotary dryer uses telescope-feed structure, which can dry the material for a short time.

- Simple design, self-insulation, improve the heat efficiency to exceed 80%.

- Using alloy steel plate, wear 3-4 times than ordinary steel plate.

- The fuel can be coal, oil, natural gas etc, dry mass and granule and powder material.

- Reduce required space for 50% compared to single drum rotary dryer.

Working Flowchart

Working Principle

The material to be dried is pushed back immediately by spiral plates when entering the drum from feeding tank and feeding chute. Because the dryer is installed in slope, material flows to the back end under gravity and rotation force, meanwhile, the dryed material are lifted by plates repeatedly and thrown down, which make the material exchange heat sufficiently with inner heat flow. In the end, water content inside the material is dried by repeatedly scattering.

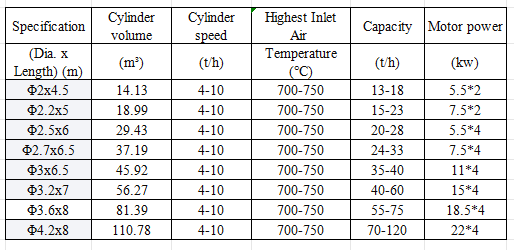

Specifications & Models

Working Video of Three layer drum dryer in the factory

Leave a Reply