Application

The reversible single-rotor sand making machines are mostly used in highway, railway, water conservancy, airport, construction, cement, resistant materials, metallurgy and other industries.

Applicable Materials

The reversible sand making machine is widely used in the fine crushing of granite, basalt, limestone, river pebbles, cement clinker, quartz stone, iron ore, bauxite and other minerals.

Features

1.Plum blossom rotor, diamond-shaped hammer plate structure, more effective in crushing, grinding and sand making.

- The grate bar can be customized, and the gap between the grate bar and the hammer head can be adjusted flexibly, which fully ensures the crushing efficiency of the hammer head.

- The shape of the finished product is full cube.

- The rotor is equipped with a high manganese and high chromium protective cover, which increases the lifespan by 30%.

- The hammer shaft hole is equipped with a tungsten alloy steel sleeve, which is more wear-resistant and impact-resistant.

- The sand making machine is equipped with an observation door, the internal conditions can be easily observed at any time, and the maintenance is more convenient.

- The hammer head is reversible, which greatly improves the utilization rate of the hammer head.

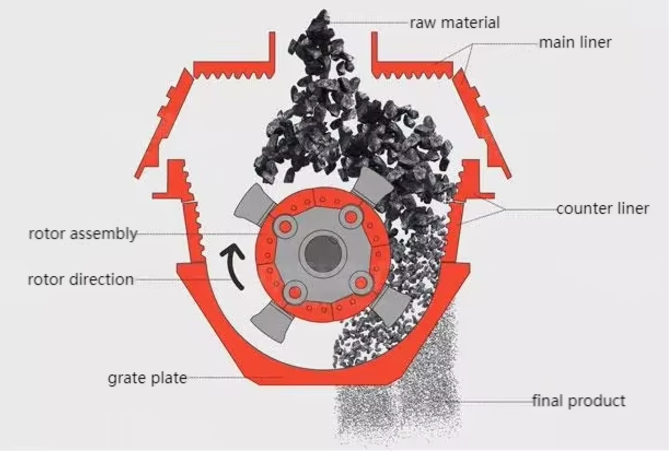

Working Principle

Reversible sand making machine is a kind of sand making machine which uses impact energy to break materials. When the machine is working, driven by the motor, the rotor rotates at high speed, so that the materials can be crushed by the plate hammer on the rotor, when the material enters the plate hammer action zone, and then the crushed materials are be pushed to the counter device to break again. This process is repeated until the materials are broken to the required particle size and discharged by the discharge port.

Single Rotor Sand Making Machine in the Workingsite

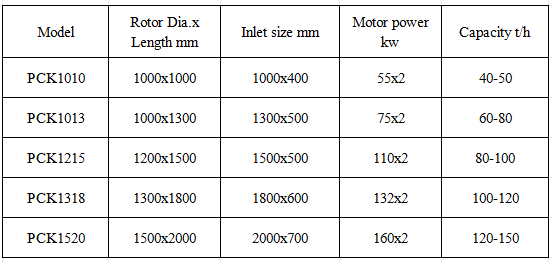

Specifications

Working Video

Leave a Reply