Applications

Jaw crusher is suitable for processing various materials with a particle size less than 1200mm and a compressive strength < 320MPa.

Ore: such as granite, quartz, river pebbles, calcite, dolomite, iron ore, silica ore, basalt, etc.

Rock: Kinds of hard stones. Because of its large crushing ratio and uniform crushed size, it is particularly suitable for the initial crushing of large rocks.

Construction waste: such as concrete fragments, bricks, construction waste, etc., which can be crushed into recycled aggregates or recyclable materials.

Industrial raw materials: such as limestone, marble, etc., these materials are widely used in many industrial fields, and jaw crushers can effectively handle and meet their processing needs.

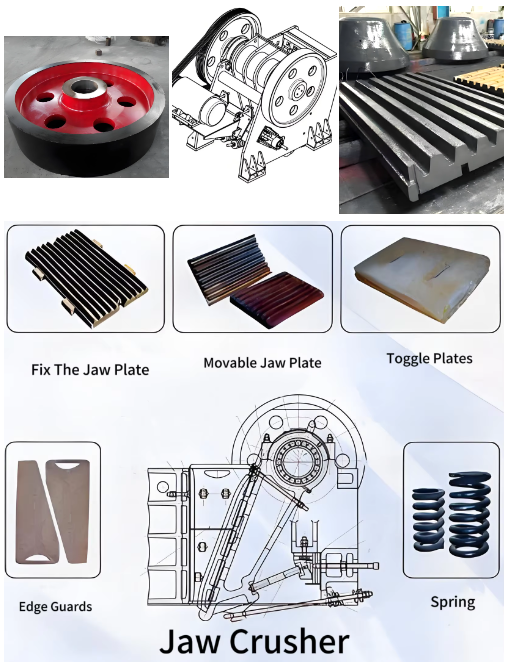

Working Principle

Jaw crusher, commonly known as jawbreaker, is a kind of crushing equipment commonly used in engineering and mining applications, and its main working parts consist of a fixed jaw tooth plate and a movable jaw tooth plate. The main working part of jaw crusher consists of a fixed jaw tooth plate and a movable jaw tooth plate, which are in periodic relative motion during the operation of the machine to realize the crushing and breaking of materials. When the movable jaw plate is close to the fixed jaw plate, the material is crushed; when the two are separated, the material moves downward due to its own weight and is discharged from the discharge opening. This design not only realizes efficient crushing, but also adds the additional effects of breaking, splitting and grinding through the tooth structure of the fixed jaw plate.

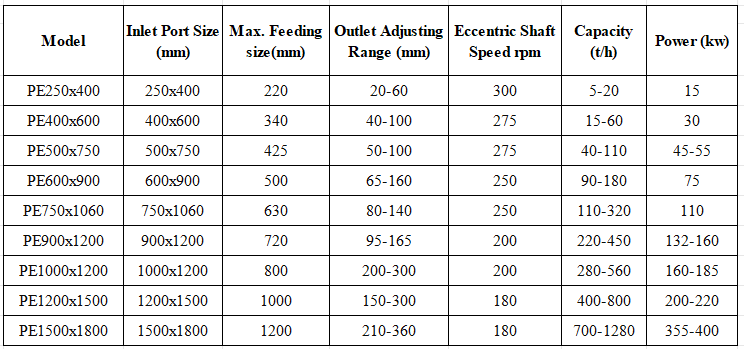

Specifications of Jaw Crusher

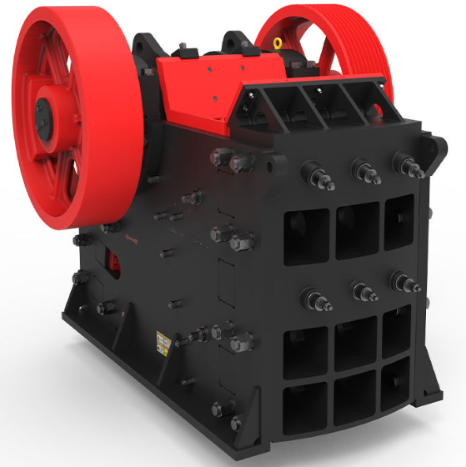

Features of Jaw Crusher

- High crushing capacity.

- Simple structure,reliable working condition.

- Easy maintenance,low operating cost.

- Ajustable discharged crushing size.

Working Video of Jaw Crusher

Jaw Crusher Workshop Show

Jaw Crusher Case

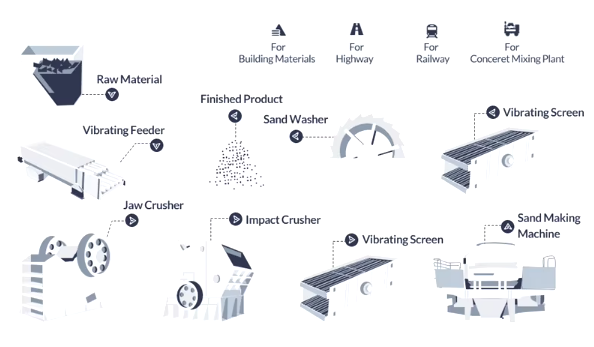

Sand Making Production Line

We can provide the whole sand production line equipment. If you need further information, please feel free to contact us.

Leave a Reply