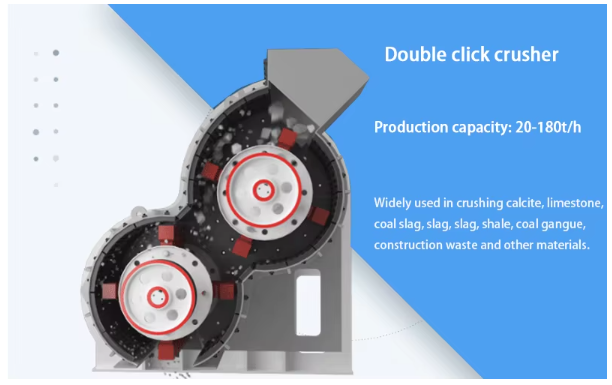

Application

The two-rotor crusher is also called the pulverizing mill, which can easily break materials with high moisture content such as gangue, shale and coal cinder etc. And the discharge particle size is 2-3mm. The double-rotor hammer crusher is used in the industries such as construction, chemical engineering, metallurgy, mine, ceramics and refractory materials. The double-rotor hammer crusher can be regarded as the combination of two hammer crushers. It adopts two sets of rotors to work together.

Pictures in our factory

Working Principle

When double-clicking the crusher, driven by double motors, the two sets of rotors connected with each other rotate at high speed at the same time. The material in the inner cavity is crushed by the upper rotor and is broken again by the hammer head of the lower rotor. forming particles with the discharge particle size less than 3mm.

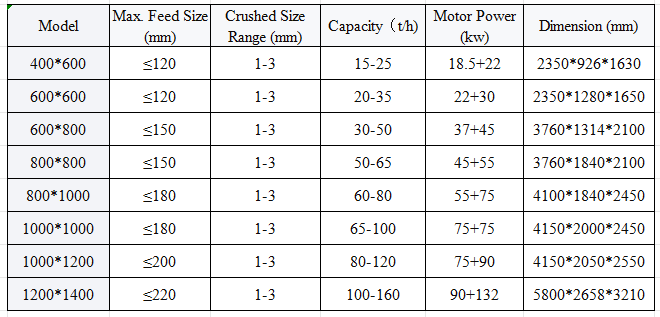

Specifications

Working Video

Leave a Reply