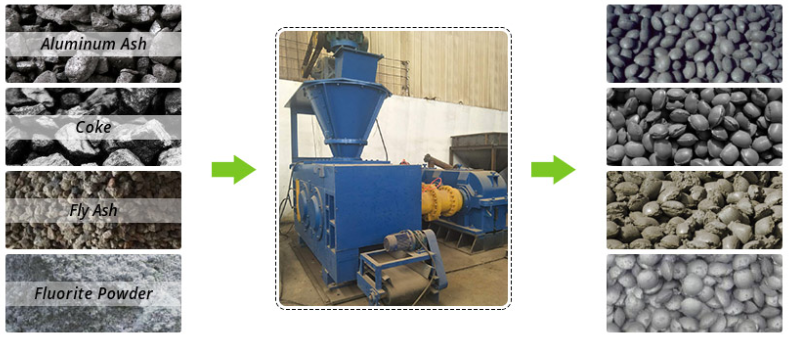

Application of DRI Briquette Machine

Sometimes, people use dual-shaft output briquette machine to process DRI powders into solid briquettes, which is with super high pressure. For this DRI briquette machines, they are also mainly used in many fields, mainly including metallurgy, chemical industry, refractory material, building materials and other industries.

Applicable Materials of DRI Briquette Machine

The applicable raw materials can be all kinds of dry fine powders, like kinds of metallic powder and mineral powder, fly ash, aluminum ash, aluminum powder, iron powder, iron oxide skin, silicon manganese ore powder, swarf, lime powder, fluorite powder, DRI powder, sponge iron fine powders, slag, gypsum, ore tailings and so on.

Features of DRI Briquette Machine

- High pressure: Leemay double-shaft briquette machine has high assembling precision, run stably and low noise.

- Continuous running performance: Dual-shaft output briquette machine is designed based on fatigue strength and 24-hour continuous run.

- Lubrication system: overall structural strength and components assembling precision can ensure continuous working.

- Longer lifespan: Two-shaft roller briquette machine is made from qualified steels, and the key parts are made from special alloy steels and advanced heat-treated to ensure the long lifespan.

- High rate of briquette forming: As the high pressure briquette machine adopts reasonable layout and reasonable compact structure, it has the high ratio briquetting ratio 95%, and also it is convenient for disassembly and assembly to reduce operation and maintenance cost.

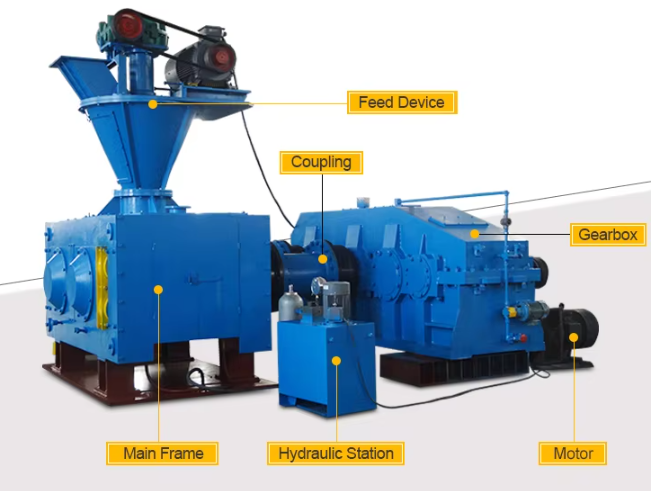

Main Components of DRI Briquette Machine

Specifications of DRI Briquette Machine

Working Video of DRI Briquette Machine

Service

Overseas third-party support available, Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service.

Leave a Reply