Application

Hydraulic pressure briquette machine is especially for processing different kinds of mineral powders, like aluminium powders, lead ash, graphite, iron powders, chromium slag, etc. The briquette machine is equipped with hydraulic system and give the high pressure to the materials with good strength.

Finished Briquettes

The finished briquettes can be all kinds of different shapes based on different molds, like square shape, spherical shape, oval shape, cylindrical shape, bread shape, pillow shape, etc. We can produce the special shapes based on customers’ demands.

Working Principle

In order to compact powders into briquettes, the raw materials need to be pre-compacted firstly, and then transported to briquette machine for compacting. There are three steps of briquetting.

Pre-compacting: pre-compacting raw materials by pre-compacting machine.

Compacting: pre-compacted raw materials flow into the two rollers of briquette machine, up to the highest pressure between two rollers.

Discharging: after compacting, the cavities will be separated gradually, with the rotation of the two rollers. The briquettes will be discharged from the cavities under its centrifugal force and gravity.

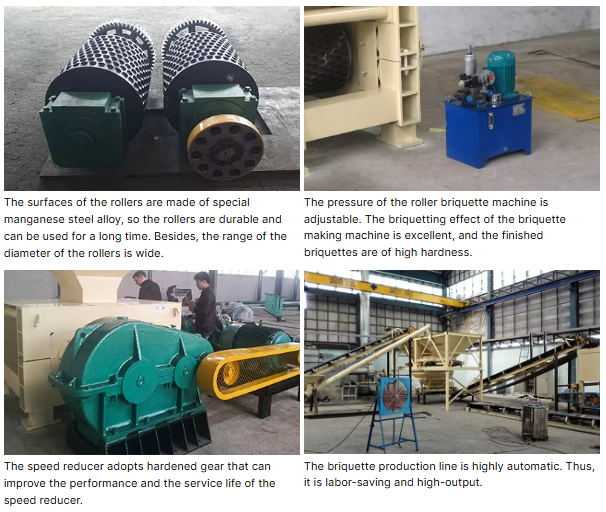

Feature

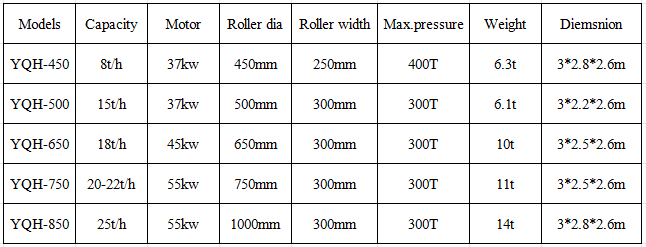

Specification

Leave a Reply