Application of Ball Mill

Ball mill is a widely used grinding equipment, which grinds materials through the collision between materials, or the collision and friction between materials and the object ,the materials are ground to the required particle size. It is widely used in the grinding process of mining, metallurgy, building materials, chemical industry and other industries for various ores, coal powder, ceramic raw materials, etc.

Applicable Materials of Ball Mill

The ball mill is suitable for grinding more than 100 kinds of materials , such as iron ore, copper ore, golden ore, river pebbles, kaolin, limestone, dolomite, granite, marble, basalt, coal, sandstone, shale, etc.

1. Grinding iron ore , non-ferrous metal ore into powder in metallurgical industry

2. Grinding various coatings, pigments and other fine chemical materials in chemical industry.

3. Grinding cement, glass and other building materials into powder in building materials industry

4. Grinding ceramic raw materials in ceramic industry.

Features of Ball Mill

1.It is an efficient tool for grinding many materials into fine powder.

2.Two ways of grinding: the dry way and the wet way.

3.Ultimate particle size depends entirely on how hard the material you’re grinding is.

4.Easy operation and maintenance.

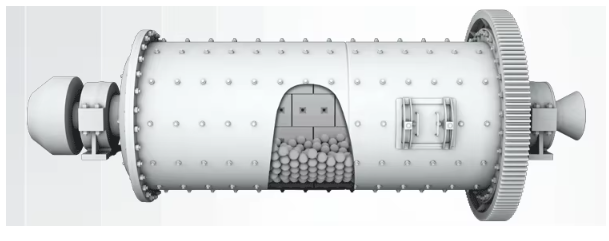

Working Principle of Ball Mill

The Energy-Saving Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of casting steel balls in the chamber. The centrifugal force caused by rotation of drum brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board, thus the grinding process is finished.

Main Parts of Ball Mill

Grinding Balls of Ball Mill

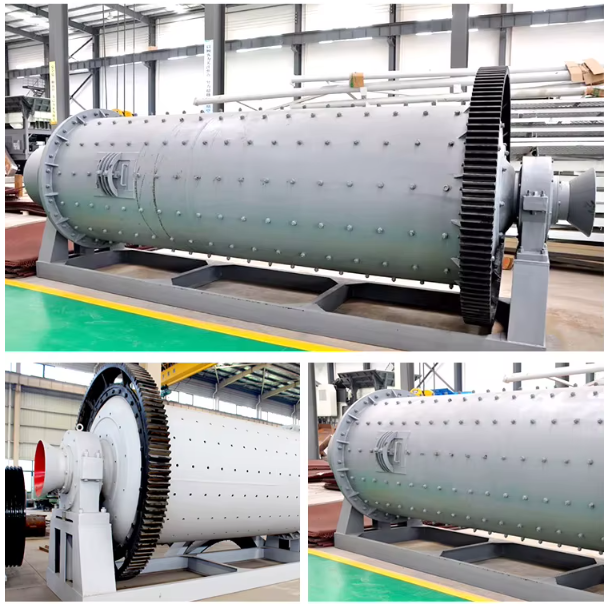

Ball Mills in Leemay Workshop

Specifications of Ball Mill

| Model | Speed of bucket(r/min) | Ball load(t) | Feeding size(mm) | Size of outputting(mm) | Capacity | Motor Power(kw) |

| (t/h) | ||||||

| 900*1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 15 |

| 900*2100 | 38 | 1.5-1.6 | ≤20 | 0.075-0.83 | 0.7-3.5 | 18.5 |

| 900*3000 | 36 | 2.5 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

| 1200*2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 |

| 1200*3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 |

| 1200*4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

| 1500*3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 |

| 1500*4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

| 1500*5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 |

| 1830*3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 |

| 1830*3600 | 24 | 10.6-11.35 | ≤25 | 0.074-0.4 | 5-22 | 130 |

| 1830*4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 185 |

| 1830*7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 210 |

| 2100*4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

| 2100*7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

| 2200*4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

| 2200*6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

| 2200*7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

| 2200*7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 |

| 2400*3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 |

| 2400*4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 380 |

| 2700*3600 | 20.7 | 39 | ≤25 | 0.074-0.4 | 12-70 | 400 |

| 2700*4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 |

| 2700*4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 |

| 3200*4500 | 18 | 65 | ≤25 | 0.074-0.4 | Depend on the process | 800 |

Working Video

Leave a Reply