-

Charcoal Crusher

Description The working principle of this charcoal powder crusher is to crush the material by the rapid rotation of the internal hammer blade and impacting the material. The crushing cylinder is designed to be inclined at 30 degrees to extend the crushing time of raw materials and increase the number of impacts between the raw…

-

Cone Crusher

The continuous technological innovation and optimized design of the cone crusher keep its strong competitiveness and wide market application in the crushing industry.

-

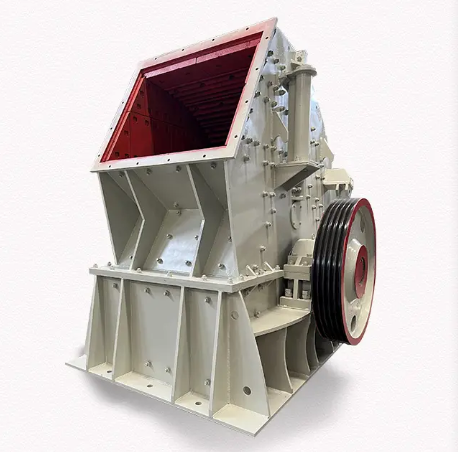

Heavy Duty Hammer Crusher

Application of Heavy Hammer Crusher Heavy Duty Hammer Crusher is suitable for fine crushing of medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highways, and combustion. Applicable Materials of Heavy Hammer Crusher Working Principle of Heavy Hammer Crusher The main working part of the machine is the rotor with hammers (also…

-

Gyratory Crusher

Applications The gyratory crusher is mainly used for the secondary and tertiary crushing of hard ore and rock in the industrial sectors such as metallurgy, mining, chemical, cement, construction, refractory materials and ceramics. The crushing compressive strength is not more than 200MPa, and the feed size is up to 450 -1000mm, average discharge size ≤ 5-8mm. Applicable…

-

Multi-Cylinder Hydraulic Cone Crusher

Applications The multi-cylinder hydraulic cone crusher is developed on the basis of the spring-safe cone crusher. It has hydraulic adjustment capabilities and stronger elastic recovery capabilities. It is also designed with more comprehensive insurance measures and is widely used in coal mining and power generation. In industrial sectors such as factories and stone quarries, it…

-

Double-Rotor Hammer Crusher for Sand Making

Application The two-rotor crusher is also called the pulverizing mill, which can easily break materials with high moisture content such as gangue, shale and coal cinder etc. And the discharge particle size is 2-3mm. The double-rotor hammer crusher is used in the industries such as construction, chemical engineering, metallurgy, mine, ceramics and refractory materials. The double-rotor hammer…

-

Box Crusher

Box-type crusher is also called heavy hammer crusher, box-type heavy hammer crusher, square box crusher, which is a stone crushing machine that integrates the advantages of jaw crusher, hammer crusher, impact crusher, snail crusher and other advanced technologies at home and abroad. The rocks with a side length of 450-1200 mm are directly broken into…

-

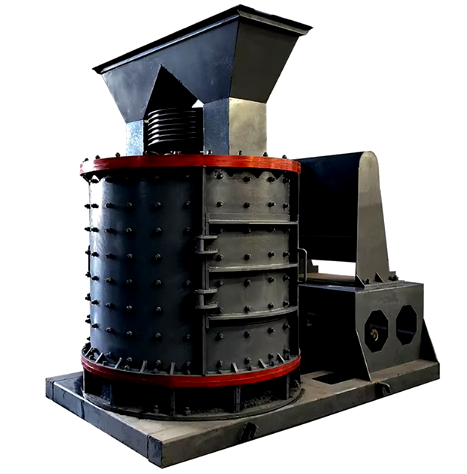

Vertical-Shaft Stone Crusher

Vertical shaft compound stone crusher is a kind of adjustable fine crushing equipment without screen bar, which is optimized and designed on the basis of absorbing domestic advanced fine crushing equipment. It can be widely used in the fine crushing operation of raw material and clinker in cement plant.

-

European Version Impact Crusher

Application European Version Impact Crusher is a kind of crushing machinery that utilizes impact energy to crush materials. This impact crushing equipment can handle all kinds of materials with particle size not larger than 1000mm and compressive strength not more than 350 MPa. It is characterized by large crushing ratio, high crushing efficiency and convenient…

-

Jaw Crusher

Applications Jaw crusher is suitable for processing various materials with a particle size less than 1200mm and a compressive strength < 320MPa.Ore: such as granite, quartz, river pebbles, calcite, dolomite, iron ore, silica ore, basalt, etc.Rock: Kinds of hard stones. Because of its large crushing ratio and uniform crushed size, it is particularly suitable for…

LEEMAY MACHINERY CO., LTD

Commitment to innovation and sustainable development.

![]() HOTLINE: +86-13592528737

HOTLINE: +86-13592528737